This year’s Prevention Forum was a premiere in two aspects. It consisted of an international and a national part and took place at the Austria Center Vienna. More than 130 speakers addressed the topics of digitalisation, Vision Zero and supply chains.

This article is also available in German: Review: Forum Prävention 2023

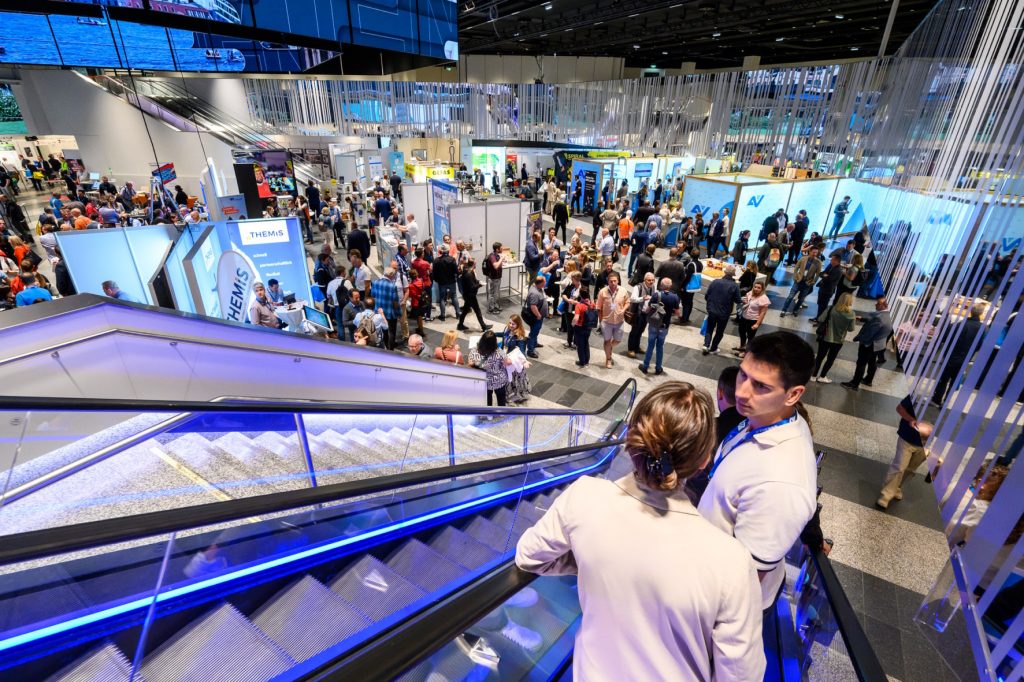

With a new concept, the Forum Prävention 2023 took into account the increasing internationalisation of work, which poses challenges for occupational safety and health, such as digitalisation and cross-border supply chains. Cross-border knowledge transfer can help provide solutions. More than 130 speakers from Germany and abroad presented their ideas and projects to around 1,200 visitors. In keeping with the international orientation, the event took place at the Austria Center Vienna.

The first half of the Prevention Forum was dedicated to the international part, which was conducted in cooperation with the International Social Security Association (ISSA). The national part was covered in tried and tested form by the working groups from the fields of occupational medicine, hospitals, ergonomics, industrial and organisational psychology, construction, the oil and gas industry, traffic and transport, and metal and electrical. 66 companies represented at the „Prävention aktuell“ trade exhibition offered an overview of products for a safe everyday working life.

In his opening speech, Jan Pazourek, Deputy Director General of AUVA, pointed out the changes of recent years and their impact on occupational safety: „The core message of the current accident statistics is: the pandemic is over. Due to the increase in activities, the accident rate has risen again, but not yet to the level of 2019. The topics of home office and digitalisation have become part of the working world and are here to stay.“ These developments are also having an impact on the nature of workplace accidents. For example, the number of bicycle accidents, which mainly affect delivery workers, has multiplied.

DI Georg Effenberger, Head of the Department for Accident Prevention and Combating Occupational Diseases at AUVA, provided an overview of the three main topics of the Forum Prävention in his presentation. „Vision Zero“, aims to ensure that all workers return home healthy and safe after each working day. “Supply Chains” and their impact on health and safety ,which have gained significant attention since the pandemic. Regarding the third focus, “Digitalisation”, the AUVA seeks to promote the positive aspects, according to Effenberger: „Our goal is to humanise the world of work. We must prioritize people.“

Keynote: Artificial Intelligence

In the field of digitalisation, progress in artificial intelligence (AI) is particularly rapid. Univ. Prof. Dr Dietmar Reinert, Director of the Institute for Occupational Safety and Health of the German Social Accident Insurance (DGUV), dedicated his keynote to the question of how to recognise trustworthy AI. Several criteria can be used to determine whether an AI functions both reliably and safely while also taking ethical aspects into account – for example, non-discrimination in recruitment.

As an example of AI contributing to greater occupational safety, Reinert described a DGUV-funded research project on accident prevention in steel production and mail and parcel delivery. With the help of algorithms to detect “almost falls”, training elements were developed to prevent tripping, slipping and falling accidents.

Keynote: the Vision Zero story

DI Helmut Ehnes, Chair of the „Vision Zero“ Steering Committee of the ISSA Special Committee on Prevention, described in his keynote how the vision of a world without occupational accidents could become a reality. The economic aspect plays an essential role, Ehnes emphasised: „Prevention is an investment: Return of Prevention. Every euro invested in safety, health and well-being has the potential to increase economic success by 2.20 euros.“

Safety, health and well-being are the three pillars of Vision Zero. While safety in the workplace is the „classic“ approach, keeping employees healthy is often undervalued. Well-being also includes mental health, which is promoted by a good prevention culture.

Keynote: fair supply chains

The opening of the Prevention Forum was concluded by the presentation of Dr Virpi Stucki, Chief of Rural Entrepreneurship, Job Creation and Human Security Division of UNIDO. She emphasised the need to make international supply chains fair and sustainable.

As examples of good practice, she cited UNIDO-supported projects that focus on both occupational safety and environmental protection, such as fair-trade cocoa from Nicaragua. Stucki is confident that everyone can contribute to sustainability: „We are all consumers. When we buy a new smartphone, we should ask the seller where the materials come from.

Digitalisation

On the focus of digitalisation, positive and negative effects of new technologies were highlighted: support in risk assessment and prevention, but also stress and safety risks.

The impact of digitalisation on the world of work varies widely. It ranges from improvements through the use of digital tools for risk assessment, training and accident prevention to increased stress and the emergence of new safety and security risks. These individual aspects were addressed by the speakers in both, the international and the national, parts of the Forum Prävention.

The DGUV’s Berufsgenossenschaft für Gesundheitsdienst und Wohlfahrtspflege (BGW) has developed an online tool to help small businesses in the health sector with risk assessment. „During the risk assessment, users are guided by questions, for example, on trips, falls, and slips. The tool enables them to identify the need for action and the appropriate measures,“ explained Dipl.-Päd. Marco Müller, Head of Product Development at the BGW. However, the expertise of professionals and individual risk assessment cannot be replaced by the tool.

Dipl.-Biol. Annegret Epple from the Berufsgenossenschaft Nahrungsmittel und Gastgewerbe (BGN) of the DGUV explained how a „company inspection 4.0“ works. A digital assistant determines a risk index based on six factors. This helps the BGN supervisors to determine the optimal frequency for company visits for each company and to create a costumised prevention concept.

AI and data glasses

Paul Martin Fechtner from the Institute for Occupational Safety and Health (IFA) of the DGUV discussed increasing occupational safety through artificial intelligence. As an example, he described a system that prevents cut injuries when working with a sliding table saw. Cameras monitor the position and movements of the hands. If they approach the danger area, this is detected with the help of AI and the user is warned. „In the event of an acute hazard, the saw blade is immediately shut down and lowered under the processing table,“ says Fechtner.

AI can also support the testing of machines. Due to the increasing workload, the inspectors of the DGUV’s testing and certification system have less and less time to inspect each individual machine, including its operating instructions. Dr. Oliver Schmitt from the DGUV’s Food Department presented a digital tool that automatically searches through the operating instructions and transfers the data to the test report. This speeds up the inspection process and guarantees high accuracy at the same time.

Augmented reality (AR) projects were presented by local companies at a presentation by the Metal and Electrical Working Group. AR is used at KNG Kärnten Netz GmbH for training purposes and to increase occupational safety, e.g. when working on switchgear. Siemens Energy Austria GmbH uses AR glasses for training and instruction for self-driving work equipment. At the mobility technology company AVL List GmbH, AR is used to support the maintenance of test benches. Patrick Christian Bauer from the PRO-GE trade union pointed out the stress caused by data glasses, including pressure points, temperature and radiation as well as stress due to complex handling.

Several speakers addressed the risks posed by digital networking. Unauthorised access to a company’s IT infrastructure can pose a risk in two ways: in the area of security for the technical systems, and in the area of safety for operational safety, thus jeopardizing the physical integrity of the employees. IFA security expert Jonas Stein reported on an attack on a German steelwork in 2014, in which malware was introduced into the system via an e-mail. The blast furnace could no longer be shut down in a controlled manner. Measures to protect the IT infrastructure, therefore, also represent a significant contribution to occupational safety.

Vision Zero

On the topic of Vision Zero, the focus was on traffic, which is also the subject of the current AUVA prevention focus „Komm gut an!“. The aim is to prevent serious and fatal traffic accidents.

Vision Zero has an ambitious goal: to create a world without occupational accidents and work-related diseases. The highest priority is to avoid fatal or serious occupational accidents and diseases. Several presentations dealt with the implementation of Vision Zero in transport, in line with the current AUVA focus on prevention.

Peter Schwaighofer, BSc, expert for road safety at AUVA headquarters, highlighted the significance of traffic accidents using the occupational accident statistics of 2022: „Although ‚only‘ ten percent of all occupational accidents – including commuting accidents – are traffic accidents, 35 percent of fatal occupational accidents occur in traffic“. To develop an efficient prevention strategy, it is essential to analyse the cause of the accidents and how they occur.

The causes of accidents in internal traffic are often not well-known, but inattention and distraction frequently play a role, noted Mag. Dr. Sylvia Peißl, a psychologist at the AUVA Graz regional office. One method to identify risks in internal traffic is the eye analysis offered by AUVA. Using eye tracking, it is possible to determine whether a driver is paying attention to the surroundings or if their field of vision is restricted by obstacles.

Distraction is the number one cause of accidents, emphasised Dipl.-Psych. Daniela Knowles from KFV. However, fatigue, illness, stress, alcohol, and other substances can also influence driving ability. In her lecture, the psychologist presented the „Driving Ability Workshop“, an AUVA offer in cooperation with the Austrian Road Safety Board (KFV), as well as the AUVA app „Fahr sicher!“ (Drive Safely!), which offers a virtual simulation of scenarios with impaired driving ability in connection with the AUVA road safety glasses.

E-scooters and bicycles

E-scooters are used for commuting to work, and partly for travel within factory premises. As part of the project „Safe e-Scooter driving“ (SEED), DI Michael Aleksa, Senior Researcher at the Austrian Institute of Technology GmbH (AIT), had volunteers navigate a course with e-scooters. Several factors were identified that contribute to safe and therefore accident-free driving: stability and braking behaviour differ depending on the type of scooter. Difficult maneuvers include navigating curves, narrow spaces, and giving hand signals.

Franz Strobl from the Vienna Labour Inspectorate spoke about accident prevention in delivery services. The appropriate means of transport – bicycle, e-bike or e-load bike or S-pedelec – as well as the appropriate transport container must be chosen according to the specific route and the load being carried; wearing a helmet and weather protection are required as personal protective equipment (PPE). The rider must be in good physical condition and knowledgeable about road traffic regulations. Further details can be found in the leaflet M.plus 801 „Bicycle Messenger Services – Safe on the Road,“ produced by AUVA and the Labour Inspectorate.

According to Christian Kräutler of the KFV, one approach to reducing the number of seriously injured and fatalities in road traffic is the concept of the „Safe System,“ where the responsibility for accident prevention is not solely placed on road users. The infrastructure can also contribute through „forgiving of mistakes“ roads, and vehicles equipped with assistance systems and a fast and efficient rescue chain can play a significant role.

Ing. Michael Nikowitz, MSc, Coordinator of Automated Mobility at the BMK, ventured a glimpse into the future of automated mobility. Driving safety will increase due to the widespread use of assistance systems. However, highly automated vehicles, where drivers do not need to focus their attention on traffic, will only be on the road in defined areas and operating environments for some time to come.

Supply Chains

Safety and health for workers do not end at the company gates. The pandemic and the Ukraine war have pointed out how interconnected and fragile global markets are.

„Our everyday lives are shaped by products that are largely not manufactured in Europe. It starts with the smartphone, continues with the clothes we wear and extends to the e-car we drive,“ says Dr Virpi Stucki, Chief of Rural Entrepreneurship, Job Creation and Human Security Division of UNIDO, during her keynote address at this year’s Forum Prävention. „The International Labour Organization (ILO) estimates that 160 million children between the ages of eleven and seventeen work in precarious employment worldwide, many of them with hazardous substances,“ Stucki continued. How goods are produced, packaged and transported today has an impact in the producing countries, along the global supply chain to the destination countries. From the sustainability perspective, the demand to consider the entire value chain has therefore been in focus for some time. Safety and health are an essential part of this. „Nevertheless, we know that only about 30% of all small and medium-sized enterprises are able to track their supply chains transparently,“ says the UNIDO expert.

Creating fair supply chains

Global platforms are needed to ensure international cooperation in the field of occupational safety and health in the trade and goods logistics sectors. Such a platform was recently created by the German Berufsgenossenschaft Handel und Warenlogistik (BGHW) and the International Social Security Association (ISSA). Long-term goals include the introduction of international OSH standards, the promotion of a global prevention culture, the reduction of global accident occurrence and the associated rehabilitation and absenteeism costs, as well as the creation of fair competitive conditions.“

Interview:

Dr Klaus Schäfer, Head of Prevention, Berufsgenossenschaft Handel und Warenlogistik (BGHW) and Technical Secretary of the Trade Section of ISSA (International Social Security Association)

Has the importance of prevention and security in global supply chains changed in recent years?

Schäfer: Yes, absolutely. On the one hand, this is due to the changed legal situation in Germany and the planned change in Europe. Furthermore, the VISION ZERO strategy is being implemented by more and more companies and customers are increasingly demanding more sustainability in products and supply chains.

Where are the major hurdles to comply with VISION ZERO in international supply chains?

Schäfer: The biggest hurdle is the complexity of international supply chains and the multi-layered nature of business and trade relationships. Insufficient information from more distant companies, trade secrets and brand protection are further problems that also raise the question: Who can be held liable at all if health and safety deficits occur along supply chains?

What measures are important to make international cooperation in trade and goods logistics more secure?

Schäfer: Important measures include, in particular, international cooperation between all stakeholders in order to establish a culture of prevention along the supply chains. This requires intensive communication, trust-building within the supply chains, exchange of knowledge and experience with best practices and the qualification of supply chain partnerships.

Many companies are struggling with the consequences of a pandemic and a shortage of skilled workers. How can they nevertheless become active for more security in the supply chain?

By anchoring occupational safety and fundamental human and labour rights in their own corporate goals. At the same time, this secures a workforce and makes the company more attractive. The status quo of the supply chain should then be determined. The next step could be to contractually demand labour protection and human rights from contractors.